Maximizing Efficiency and Performance: The Case for Upgrading

- lhafley

- Jan 12, 2024

- 4 min read

Fastener Technology International Magazine

December 2023/January 2024

Written by: Brett Kuhn

Customer Support Manager

National Machinery LLC

Listening to feedback from customers led to the development of a variety of upgrades and enhancements to FORMAX® machines.

Since its inception in 1989, FORMAX® has not only stood

the test of time but along the way has actively undergone

continuous improvement. Formax machines built today are

vastly improved from those first machines. Utilizing customer

feedback, National Machinery engineers have made

countless upgrades and enhancements. Virtually all major

components have been improved—from feed, to transfer, to

heading slide. The number one rule along the way has been

this: every design change must be retrofittable. That means

that whatever the vintage of your FORMAX, there is an opportunity

waiting to bring it to today’s standard.

Let’s explore the advantages of rebuilding your FORMAX

to incorporate these technological advancements so that you

get the most out of your machine.

Technological Improvements

The Table seen below presents a list of upgrades that will

allow you to get the most out of your FORMAX.

For this Rebuild and Upgrade Emphasis article, let us

drill in on several specific upgrades, in order to examine the

benefits of upgrading to today’s standard.

Updated Electrics/Controls: FORMAX machines are

designed to give decades of service as shipped, but we all

know that electrical components become obsolete much

sooner than mechanical components. When we do need to

update obsolete electrical components, the good news is that

we can get increased functionality beyond simply replacing

“in kind.” For FORMAX machines, the most interesting

example is the incorporation of remote connectivity solutions.

By allowing access to your machine’s control system

through an EWON communications system, you can not only

utilize machine data to enhance productivity, but also allow National’s support team to remotely connect to your machine

for troubleshooting, reducing your machine’s downtime. In

recent years, we have all experienced extensive lead-times

for electrical components. Taking a proactive approach by

replacing controls before a failure can be crucial to avoid

unplanned downtime.

Transfer Housing Upgrade: Efficient high-speed machine

operation relies heavily on the transferring system. To capitalize

on their repeatable setup feature, FORMAX machines

require transfers capable of accommodating complex parts,

maintaining tight tolerances and sustaining high production

rates. Our Transfer housing upgrade incorporates features such

as a zero-clearance transfer slide, positive flow slide lubrication,

increased rigidity, locked positioning and hardened surfaces

for clamping and pivot bushings. These enhancements

contribute to improved long-term part indexing accuracy,

reliability and component durability. The transfer system can

also integrate hydraulic clamping for swift, easy and precise

changeovers, ultimately enhancing machine uptime and productivity.

The FORMAX 2000 Transfer is compatible with

all vintage and size FORMAX machines featuring the straight

across transfer configuration.

Case Study Examples

Now let us examine several case studies that are centered

around the above upgrades.

Case 1: Electrical Upgrade—Avoiding the Cost of Unplanned

Downtime: The Pareto chart on the top of the next

page illustrates the top contributors to machine downtime for a

real-life customer’s vintage 2001 FX35M over the past year. In

total, this specific machine had 500 hours of downtime related

to maintenance support, with more than 65% of downtime

being related to electrical components issues.

Key Assumptions include maintenance hourly rate of

US$35.00 and lost revenue hourly rate: US$400.00

With these assumptions, the estimated cost of maintenance

time loss is US$12,250 and the approximate lost revenue is

US$100,000, resulting in a US$112,250 cumulative loss that

could have been prevented with the simplified electrics and

wiring harness upgrades.

Case 2: Electrical Upgrade—Using Virtual Service

Support to Avoid Unplanned Downtime: In another real-life

scenario, one customer recently implemented a controls

upgrade, and soon after realized the added functionality of

remote machine access. During the weekend operation, the

customer faced a “Machine Down” situation. After some

initial troubleshooting, the maintenance personnel contacted

National Machinery’s 24/7 hotline for support. From here, our

Customer Support Representative initiated a Virtual Service

call with one of our experienced Electrical Engineers.

After reviewing the fault codes found within the program

of the machine, the problem was determined to be a damaged

kick-out adjustment sensor. He guided the customer in replacing

the sensor and calibrating the settings. The total cost of

the virtual service call was US$450.

Without the ability to provide remote Virtual Service, the

path to a solution would have been very different. Dispatching

a technician on Monday, with arrival on Tuesday, would result

in a three-day delay and a substantial loss in revenue. The total

cost of the “in-person” service call including travel expenses

and other charges, would be nearly US$6000. Add an extra US$10,000 in lost revenue, and the total cost impact would have been US$15,000. This virtual service call made possible by the simplified electrical upgrade, not only saved calendar time, but also prevented unnecessary costs and lost revenue.

Case 3: Transfer Housing and Heading Slide Upgrades—

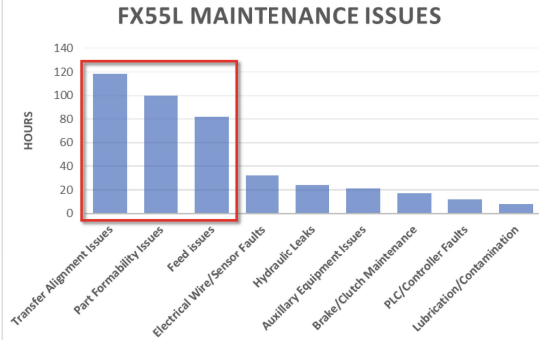

Increasing Quality and Reliability: The Pareto chart provided below presents another example from a customer, revealing the primary factors contributing to the downtime of their vintage 1997 FX55L machine. Most notable were the challenges associated with holding part length and quality, which accounted for 300 hours of downtime last year. The specific part this customer was trying to produce had exotic features and extremely tight tolerances. This requires a machine to uphold high precision and repeatability.

At the time, the machine operated at 120 strokes per minute

(SPM). Any increase carried risk of parts dropping, and overall

decline in the required quality standards for parts produced.

Complicating matters was the machine’s age, featuring the

original carbide puck liner and pre-Formax 2000 transfer.

More than 70% of the recorded downtime for this machine

was associated with challenges in part control and precision.

After consulting our Technical Support group, the customer

opted to invest in both the FORMAX 2000 Transfer Housing

and Heading Slide Liner upgrades. Following the successful

installation of these upgrades, the machine’s operational

speed surged to over 200 SPM, resulting in a 67% increase in

production. The increase in productivity directly translates to

a considerable increase in revenue for the customer.

Summary

The design improvements made to FORMAX over the

years can be added to your FORMAX machine, no matter

the vintage. The modular standardized design of FORMAX

allows it to be easily upgraded, whether as part of a machine

rebuild or as a targeted project in your plant. Upgrading your

National FORMAX machine can significantly enhance efficiency, performance and maximize the value of your investment.

Company Profile: National Machinery is a global leader in advanced

cold forming machinery, process technology and customer support products

and services. Through continuing R&D, advanced manufacturing

capability and global sales and service network, National has established

its position as the “World Leader in Metal Forming Technology”.

We strive to be focused on long-term growth through market and technical

leadership. www.nationalmachinery.com

Comments